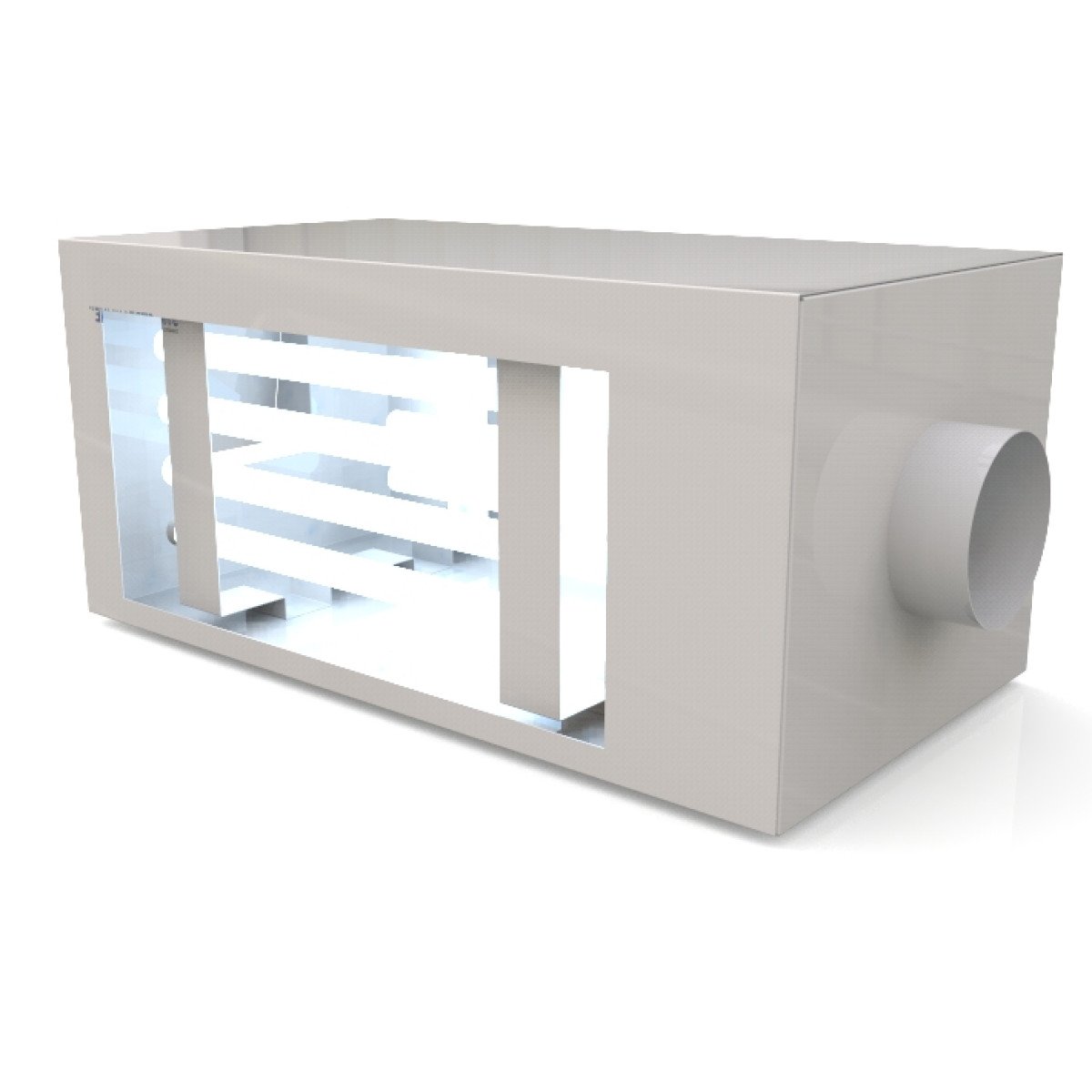

- Model: UVO-1000

- Weight: 35.00kg

- Dimensions: 800.00mm x 300.00mm x 300.00mm

How Ozone Works in Odor Control

Ozone (O₃) is a powerful oxidizing agent that reacts with odor-causing molecules, breaking them down into simpler, non-odorous compounds like carbon dioxide and water. In a commercial kitchen setting, ozone can:

- Neutralize grease vapors, volatile organic compounds (VOCs), and other airborne contaminants.

- Reduce odor intensity by chemically altering odorous molecules.

- Act as a secondary layer of filtration, complementing other systems like activated carbon and pre-filters.

Performance of Ozone for Specific Kitchen Applications

High-Smoke Cooking (e.g., Grilling, Barbecue):

- Ozone can oxidize grease-laden smoke and reduce odors.

- Requires higher ozone concentration due to the dense contaminants in the exhaust.

Spicy and Aromatic Cooking (e.g., Indian and Chinese Kitchens):

- Effective for neutralizing strong, lingering odors from spices and oils.

- May need additional pre-treatment to handle particulate matter before ozone treatment.

Low-Odor Cooking (e.g., Bakeries, Pizza):

- Ozone is highly effective in environments with lighter odor loads, requiring lower concentrations.

Advantages of Ozone for Kitchen Odor Control

- Efficient Odor Neutralization: Ozone directly reacts with odor molecules, making it effective against strong cooking odors.

- Reduces Grease Build-Up: Oxidizes grease particles in the air, potentially reducing maintenance needs for ductwork and exhaust fans.

- Chemical-Free Odor Removal: Unlike some chemical odor neutralizers, ozone does not leave residues.

- Can Work with Other Systems: Complements activated carbon and mechanical filters for a multi-layered approach to odor and contaminant removal.

Challenges and Considerations

Health and Safety:

- Ozone is toxic at high concentrations and can harm respiratory health.

- Systems must ensure that ozone levels in occupied spaces comply with safety standards (e.g., OSHA's permissible exposure limit of 0.1 ppm).

System Design:

- Ozone needs sufficient contact time to react with contaminants before being neutralized.

- Proper placement of the ozone generator in the exhaust system is crucial—usually upstream of filters or UV systems.

Pre-Filtration Required:

- Grease and particulate matter can hinder ozone's performance, so high-efficiency pre-filters (like bag filters or electrostatic precipitators) are often necessary.

By-Products:

- Ozone can react with some substances to produce secondary by-products like formaldehyde, which may require further filtration.

Maintenance and Monitoring:

- Regular maintenance of the ozone generator and monitoring of output levels are essential to maintain performance and safety.

Best Practices for Using Ozone in Commercial Kitchens

- Integrate with Other Systems: Combine ozone with activated carbon or mechanical filtration for comprehensive odor control.

- Control Ozone Levels: Use automated controls to ensure safe and effective ozone concentration levels in the exhaust.

- Pre-Treat Air: Install grease and particulate filters upstream to improve ozone's efficiency and protect the system.

- Neutralization Stage: Include a catalytic converter or UV system downstream to neutralize residual ozone before air is exhausted.

When to Consider Ozone for Odor Control

Ozone is most suitable for kitchens with persistent or strong odors, high grease content, or where compliance with strict odor control regulations is necessary. It is particularly effective in:

- Indian and Chinese restaurants.

- Barbecue and grill-heavy kitchens.

- Large-scale catering facilities.

Conclusion

Ozone can be a highly effective odor control solution for commercial kitchens when used as part of a well-designed ventilation system. However, its implementation requires careful consideration of safety, proper integration with pre- and post-filtration systems, and adherence to local health and environmental regulations. If these factors are addressed, ozone can significantly enhance air quality and reduce maintenance requirements in commercial kitchen.