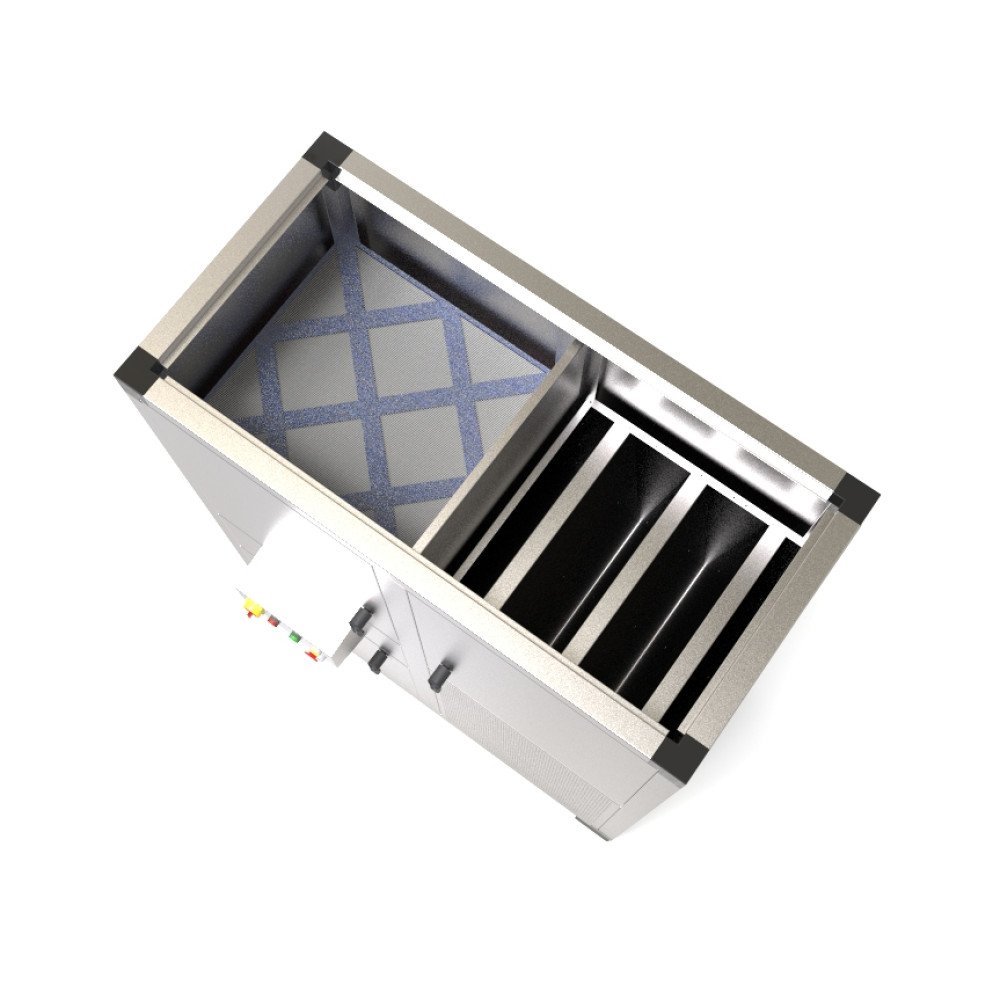

- Model: Commercial Ductless Extraction 1500plus

- Weight: 360.00kg

- Dimensions: 700.00mm x 700.00mm x 2,000.00mm

Available Options

Recirculating kitchen cooker hood | No ducting needed | Ready for Class E Planning

Commercial recirculating kitchen ductless kitchen canopy cooker hood systems are designed to address ventilation needs without requiring ductwork. Instead of venting outside, these systems filter and treat the air, making them a potential solution for kitchens where traditional ducted ventilation is not feasible or presents an issue with fire safety or is just not feasible for many other reasons.

Some issues that commercial recirculating systems solve:-

- No external ducting routes available

- No clear "Fire Safe" route

- No planning approval

- Normal system is too loud

- Flexibility to relocate the unit

- Reduced Installation costs

Ductless Modular Recirculation or Hybrid Ventilation: Choose between a ductless system that recirculates air or a hybrid model that vents steam and heat externally.

Overcome Planning Restrictions: Install kitchens virtually anywhere without the need for traditional ductwork, making it ideal for listed buildings, basements, airport terminals, and more.

Simplified Compliance: The self-contained design eliminates the need for exhaust paths that break fire barriers, enhancing fire safety and simplifying planning permissions.

Modular construction

This modular ductless filtration system can be seamlessly integrated into existing commercial kitchen setups, allowing operators to upgrade their ventilation without replacing the entire hood. Designed for flexibility, it adapts to various kitchen configurations and offers multi-stage filtration, effectively capturing grease, odors, and particulates. Ideal for spaces with limited access to external ducting, it provides a practical and energy-efficient solution for maintaining air quality while minimizing disruption during installation or retrofitting. Perfect for those looking to enhance or modify their current kitchen environment.

Exceptional Performance and Cost Savings

Energy Efficiency: Equipped with energy-efficient fan motors and controls to reduce operating costs.

Advanced Filtration: High-efficiency filters remove contaminants like grease, smoke, and odours, with longer filter lifespans for reduced maintenance.

Silent Operation: Built-in sound attenuation ensures quiet performance, creating a more pleasant kitchen environment.

Premium Construction

Durable Materials: Constructed with double-skinned panels available in kitchen-grade stainless steel or galvanized steel.

Modular Design: Offers both modular construction for easy assembly and fully assembled options to suit your needs.

Wide Airflow Range: Handles airflow from 0.5 m³/s to 4.0 m³/s with odour dwell times of 0.2 seconds or greater.

Downloads

Drawing and system specification document

Overview

The Multi-Configurable Pollution Control Unit is engineered to provide unparalleled flexibility and efficiency for commercial kitchen ventilation needs. Its adaptable design allows for vertical or horizontal installation, catering to both left-handed and right-handed kitchen setups.

Key Features

1. Versatile Configuration

Vertical or Horizontal Installation: Fits any kitchen layout.

Left-Handed or Right-Handed Setup: Customizable to your operational flow.

Modular or Fully Assembled Options: Choose the setup that suits your project timeline.

2. Advanced Air Purification

Ductless Recirculation: Eliminates the need for external ductwork.

Hybrid Ventilation Option: Allows for external venting of steam and heat if required.

High-Efficiency Filters: Removes grease, smoke, and odours effectively.

Extended Filter Life: Reduces maintenance frequency and costs.

3. Premium Construction

Double-Skinned Panels: Enhances durability and thermal insulation.

Material Choices:

Kitchen-grade stainless steel

Galvanized steel

4. Energy Efficiency and Quiet Operation

Energy-Efficient Fan Motors: Lower energy consumption without compromising performance.

Built-In Sound Attenuation: Ensures quiet operation, contributing to a better kitchen environment.

5. Safety and Compliance

Self-Contained Design: Prevents the need for exhaust paths that break fire barriers.

Simplified Planning Permissions: Ideal for locations with strict planning regulations.

Technical Specifications

Airflow and Performance

Airflow Capacity: 0.5 m³/s to 4.0 m³/s

Odour Dwell Time: 0.1 seconds or greater

Grease and Particulate Removal: High-efficiency filtration systems

Electrical Requirements

Power Supply: 220V/50Hz

Control Systems: Advanced controls with user-friendly interfaces

Dimensions

Modular Sizes: Configurable to fit various space requirements

Weight: 300 kg - 1800kg

Installation and Maintenance

Easy Installation: Modular design simplifies the installation process.

Maintenance Access: Convenient access panels for quick filter changes and servicing.

Longer Filter Lifespan: Reduces downtime and operational costs.

Applications

- Restaurants and Cafés

- Fast Food Chains

- Commercial Kitchens

- Architectural Projects

- Heritage and Listed Buildings

- Basement Installations

- Airport Terminals

| TECHNICAL | |

| Air Flow Volume | 1800 m3/hr: 365 kg: 3.6 Amps |